automation through robotics

Robotic Services

We help lower production and packaging costs by reducing the need for manual labor through advanced robotics and automation. From robotic pick-and-place systems to custom robotic cell design using cobots or industrial robots, our solutions streamline operations, increase accuracy, and accelerate throughput—so you can reach your goals faster, with greater consistency and efficiency.

Core Capabilities

- Fully Custom Designed Solutions – Tailored systems to meet specific production needs.

- Streamlined Production & Packaging – Improve speed and efficiency across processes.

- Reduced Reliance on Manual Labor – Automate tasks to limit repetitive, labor-intensive work.

- Advanced Robotics Integration – Enhance efficiency, safety, and precision.

- Faster, More Consistent Operations – Achieve higher output with reliable performance.

- Lower Labor Costs, Higher Productivity – Maximize ROI through automation.

- Custom Cell Design – Flexible layouts built for unique requirements.

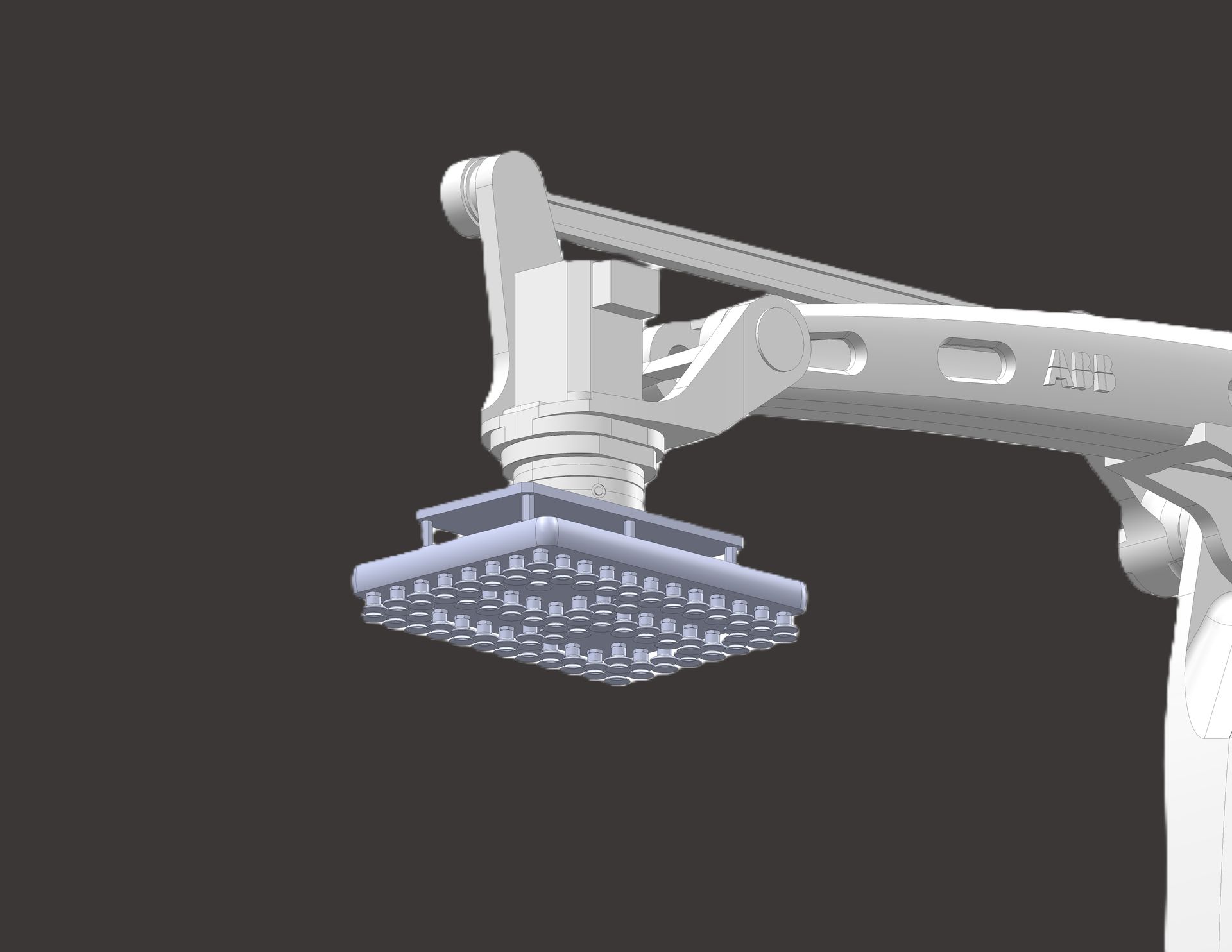

- Customer EOAT Design – End-of-arm tooling designed for specific applications.

- Off-the-Shelf Palletizing/Depalletizing – Standard solutions for quick, effective implementation.

- Controls Implementation – Seamless integration of automation and control systems.

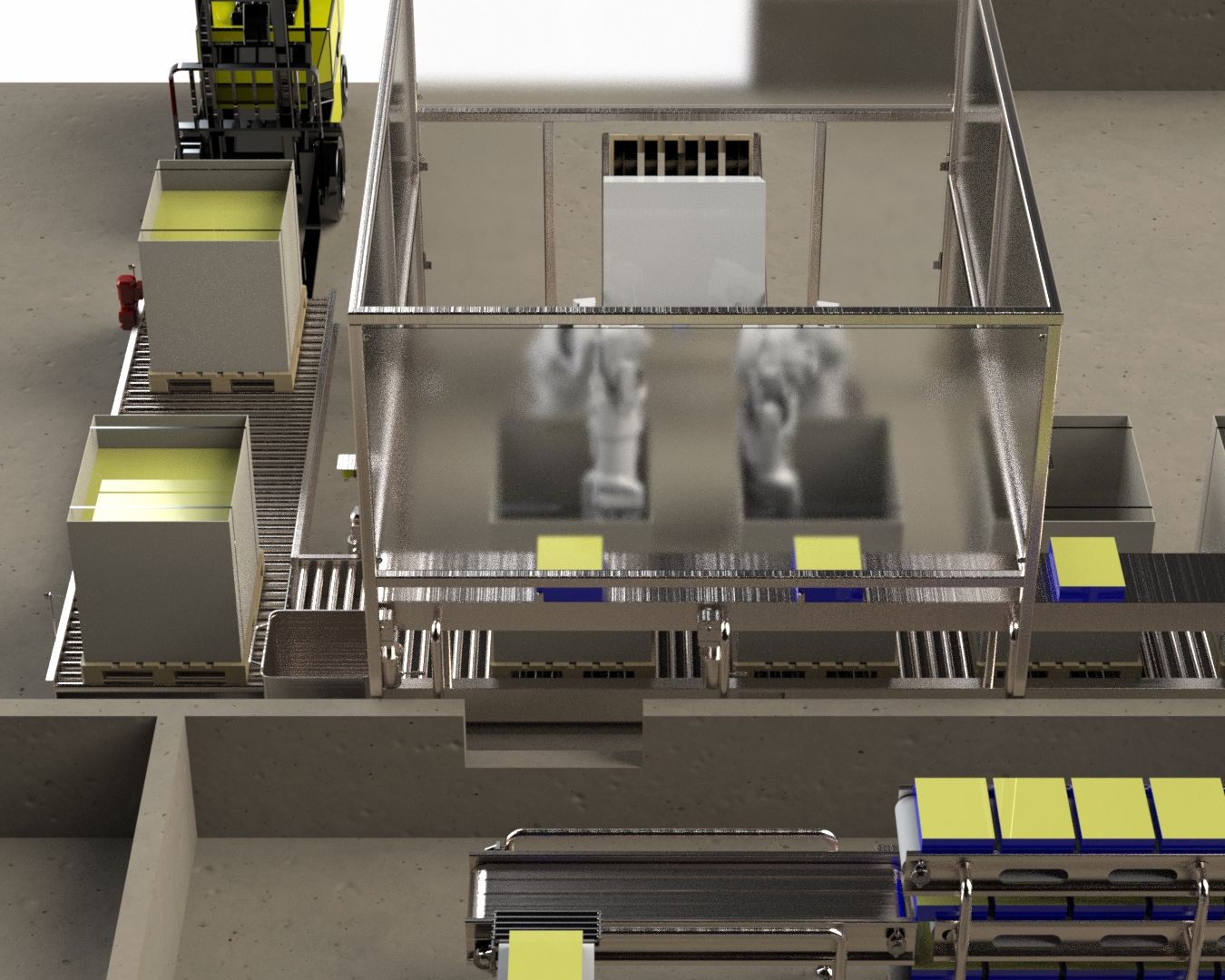

Palletizing & Case Packing

Palletizing and case packing solutions are essential for dairy and food manufacturers seeking efficiency and reliability. Automation experts design, integrate, and install systems that seamlessly connect with conveyors, labelers, metal detectors, and vision systems. From customized end-of-arm tooling and pallet configurations to automated case erecting and packing, these solutions enhance speed, reduce labor costs, and improve safety; delivering a strong return on investment for every facility.

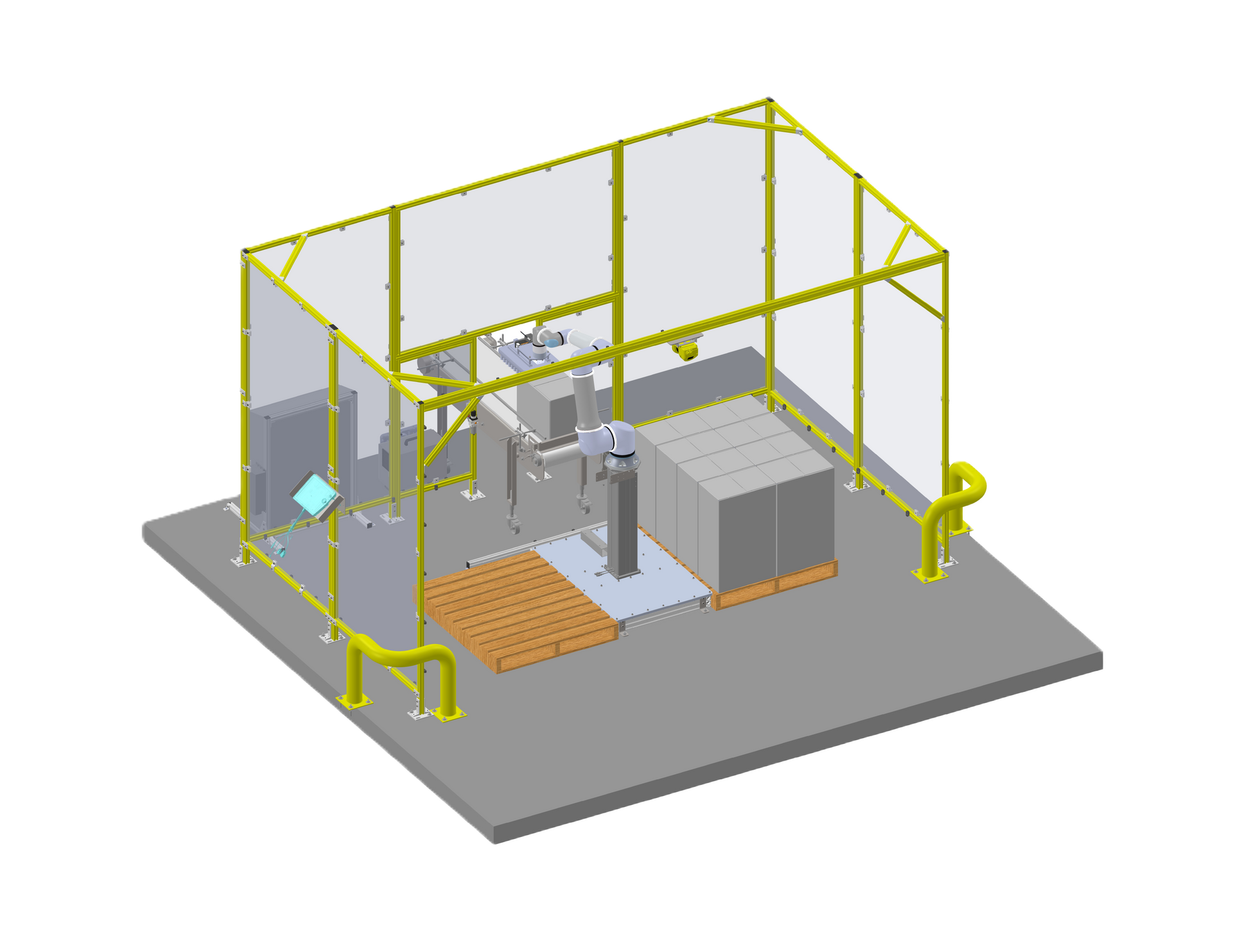

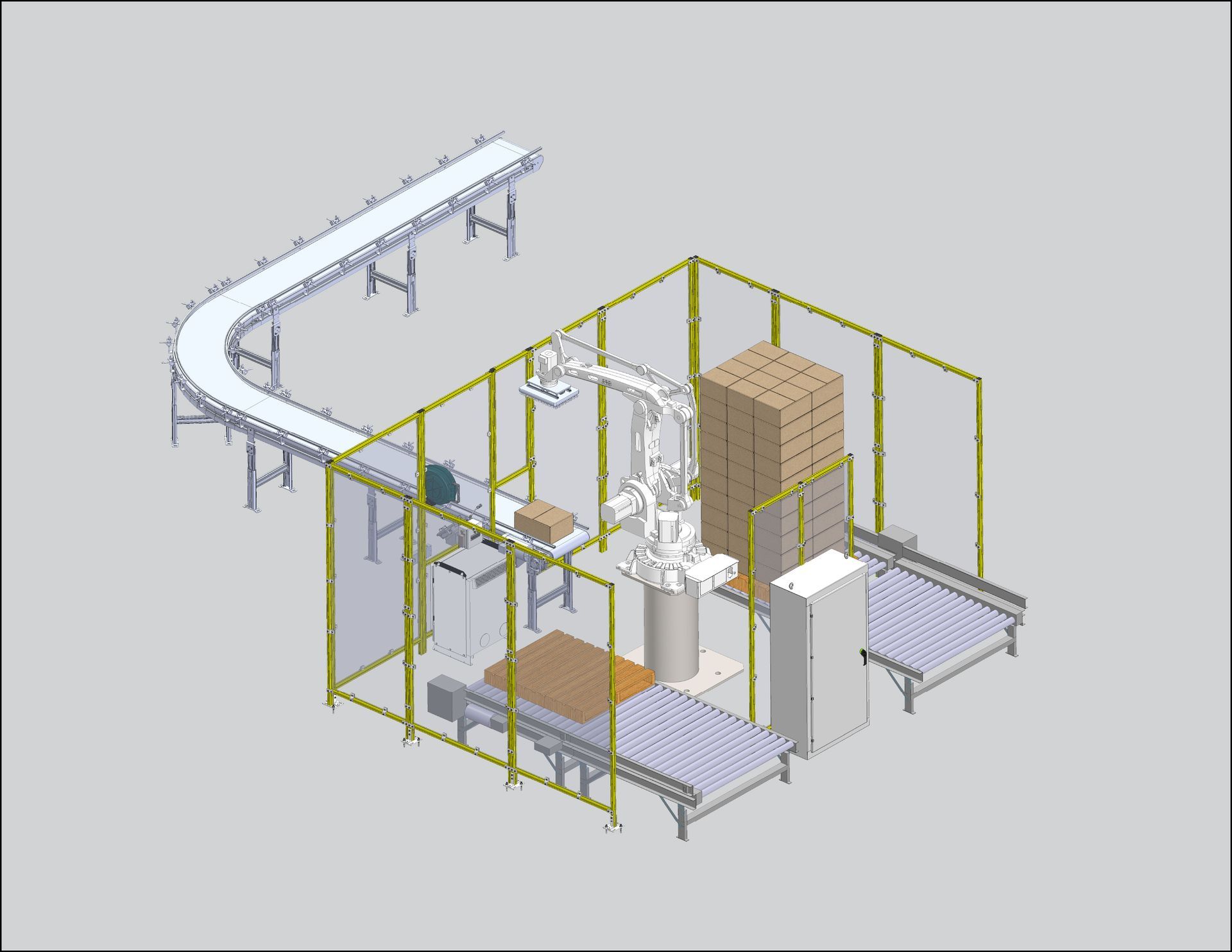

Customized Robot Cells

Customized robot cells are engineered to meet the specific production needs of each facility, offering flexible, high-performance automation for tasks such as packing, palletizing, product handling, and assembly. These turnkey systems are designed for seamless integration with existing equipment, optimizing workflow, safety, and efficiency. By tailoring every component - from tooling and guarding to programming and controls—manufacturers gain a reliable, scalable solution that maximizes productivity and consistency.

Full Controls Integration

Full controls integration ensures every aspect of your automation system works together seamlessly - from robotics and conveyors to vision systems and packaging equipment. By unifying hardware and software through expertly designed PLC, HMI, and SCADA systems, facilities gain complete visibility and control over production. This integrated approach enhances system reliability, simplifies troubleshooting, and enables real-time data monitoring for improved efficiency, uptime, and overall plant performance.

Customized Robotic Solutions with Ongoing Support

Robotics for Sanitary Plant Efficiency

Boost efficiency and safety in your sanitary plant with advanced robotic systems. Designed for strict hygiene standards, our solutions reduce contamination risks, cut labor costs, and deliver consistent, reliable performance in packaging and production.

Photo & Video Highlights

Industrial Robot palletizing bagged product.

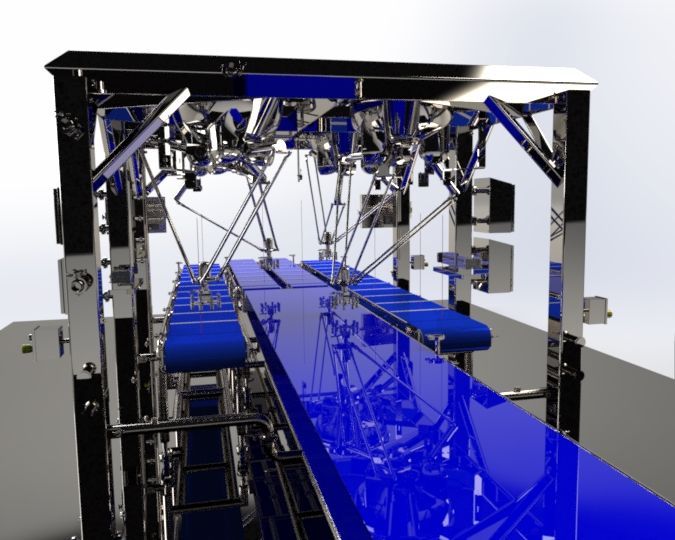

Delta Robot stacking pizza crust.

Food safe industrial robot mixing cheese.