TURNING DATA INTO action

Automation & Control Services

Our Control Team helps plants run smarter by combining real-time data, automation, and performance insights. Our controls team offers full-service controls integration. From custom panel design to HMI design with real-time reporting data, we deliver the tools to keep your operation performing at its best.

We also design telemetry systems to monitor critical resources such as water and DI water, while replacing manual data collection with automated solutions—saving time, reducing errors, and unlocking better decision-making.

Core Capabilities

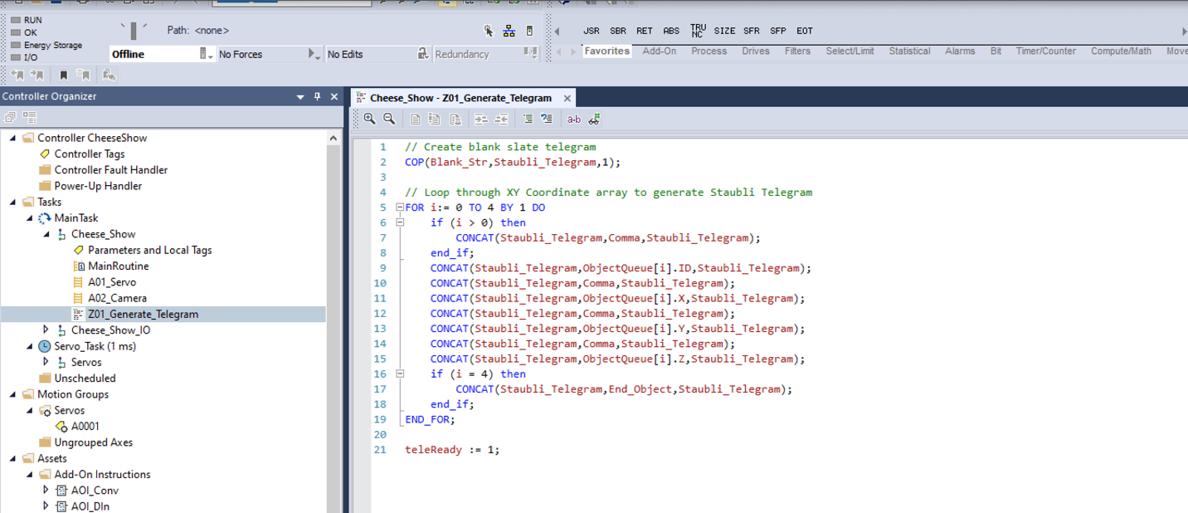

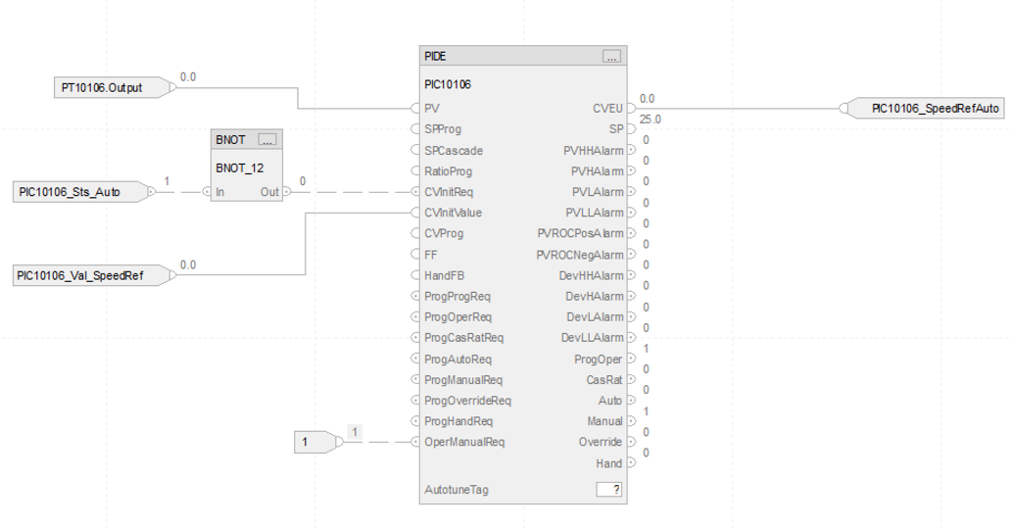

- PLC Programming - Fully automated controls for process equipment, digital systems, or robotic machines.

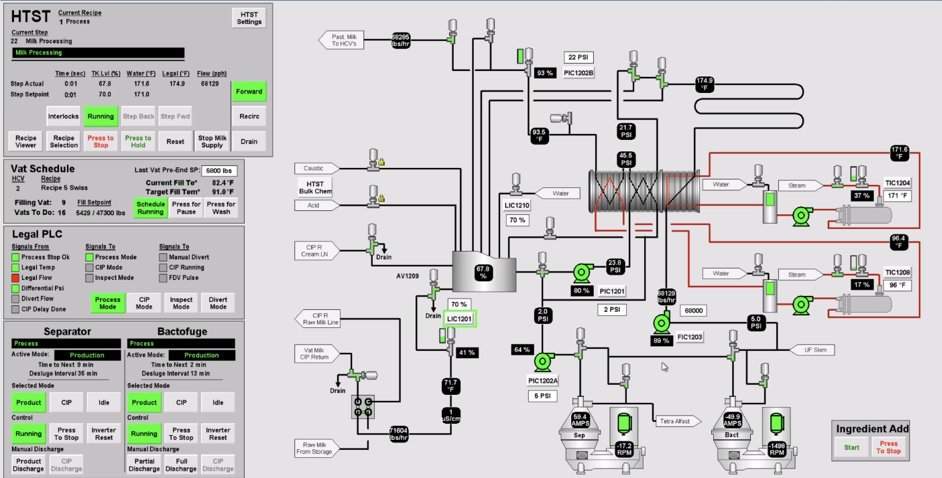

- HMI Design - User-friendly control interfaces for efficient operations, easy troubleshooting, and quick maintenance.

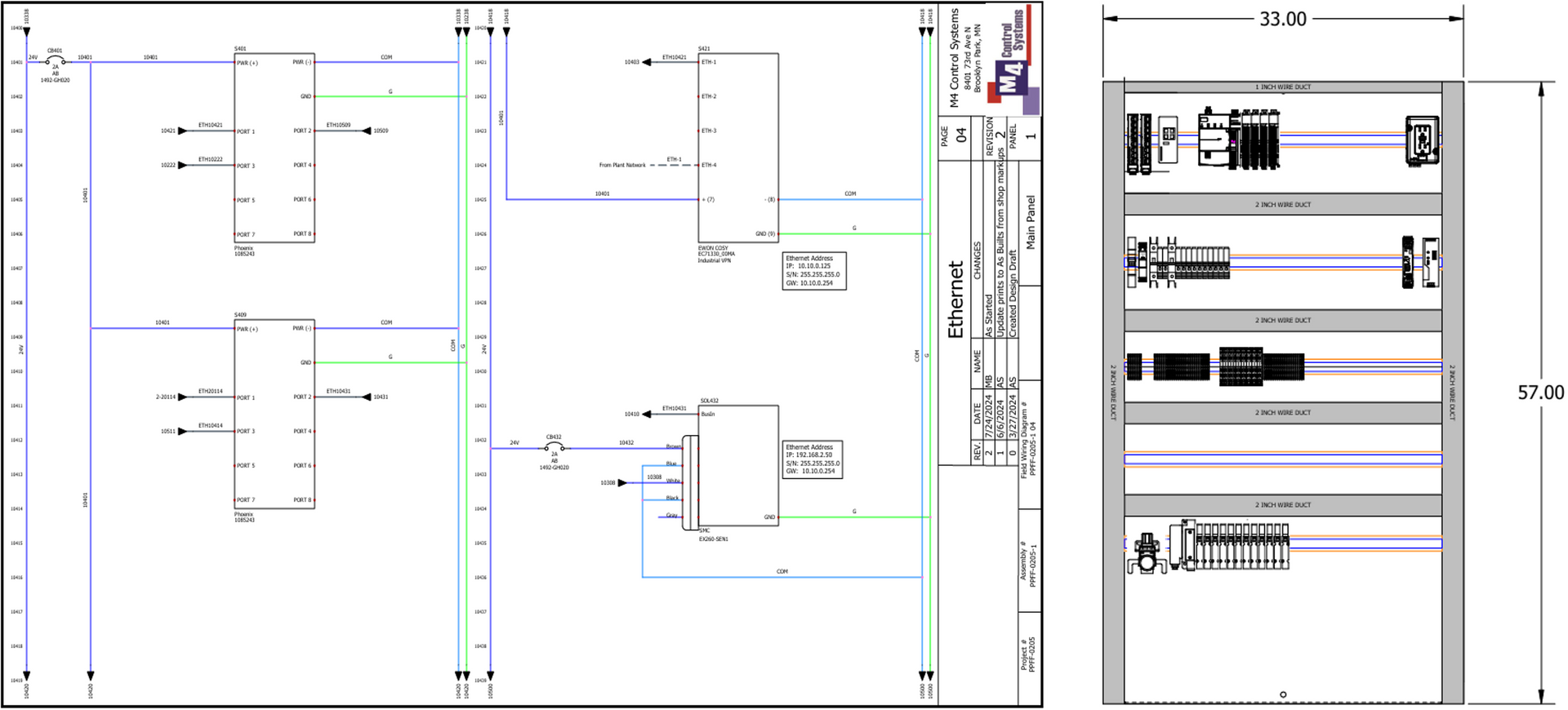

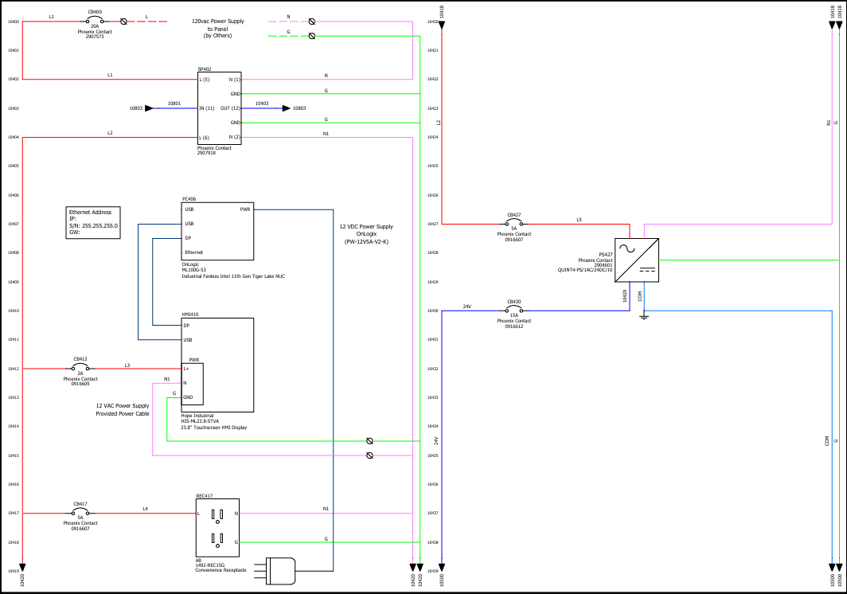

- Electrical Panel Design – Safe, reliable, and performance-driven custom panel solutions.

- Electrical Install, Debug & Commissioning – Proper setup, testing, and validation for smooth system operation.

- OEE & Database Reporting – Track overall equipment effectiveness and enable preventative maintenance.

- Real-Time Scoreboards – Measure and display plant productivity for continuous improvement.

- Telemetry Systems – Monitor critical resources such as water and DI water usage.

- Automated Data Collection – Eliminate manual entry to improve accuracy and efficiency.

- Preventative Maintenance Insights – Reduce downtime and extend equipment life.

- Historical Data Recording & Trending – Insightful performance tracking for optimization and troubleshooting.

- Customer Support – 24/7 assistance to ensure reliability and customer satisfaction.

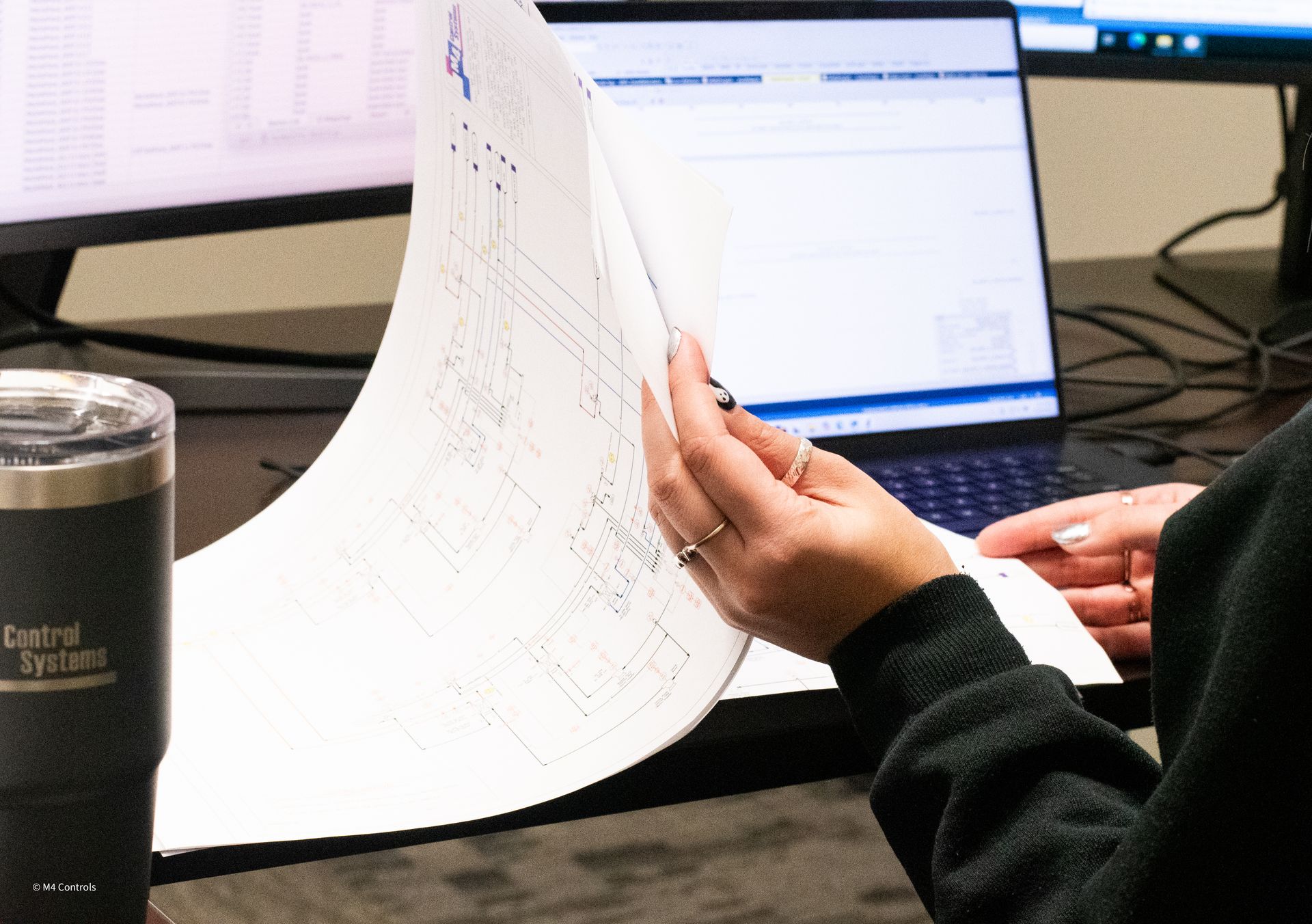

PLC Programming & HMI Design / Historical Data

PLC programming and HMI design work together to automate processes and create user-friendly interfaces for operators to monitor and control equipment. Coupled with historical data collection, these systems provide valuable insights into performance trends, allowing for better decision-making, troubleshooting, and continuous improvement.

Electrical panel design and installation ensure that systems are built to meet safety, performance, and operational requirements. Through careful design, installation, debugging, and commissioning, panels and electrical systems are verified to function correctly, supporting reliable operation and minimizing downtime.

Customer Support

Customer support is a critical part of building trust and loyalty, and offering 24/7 assistance ensures customers always have access to help when they need it. This commitment not only improves customer satisfaction but also demonstrates reliability and dedication to meeting customer needs at any time.

Comprehensive Plant Performance Monitoring, Reporting, and Data Management Solutions

Advanced Performance Monitoring & Reporting

Enhance your plant’s performance with smart data and monitoring solutions. OEE and database reporting provide valuable insights for preventative maintenance, helping reduce downtime and extend equipment life. Real-time scoreboards, similar to Redzone, give teams a clear view of productivity to drive continuous improvement. Telemetry systems track critical resources like water and DI water, while automated data collection eliminates the need for manual entry—improving accuracy, efficiency, and decision-making across your operations.