THE CORE OF m4: PROCESS EXPERTISE

Process Design Services

At M4, process is more than a step—it’s the main ingredient of our success. Our Process Team helps define labor costs, improve efficiency, and strengthen profit margins, making it a cornerstone of our business model. By focusing on smart, well-designed processes, we give our customers the tools to run stronger, leaner, and more profitable operations.

Core Capabilities

- Equipment Selection – Choosing appropriate equipment based on goals and objectives.

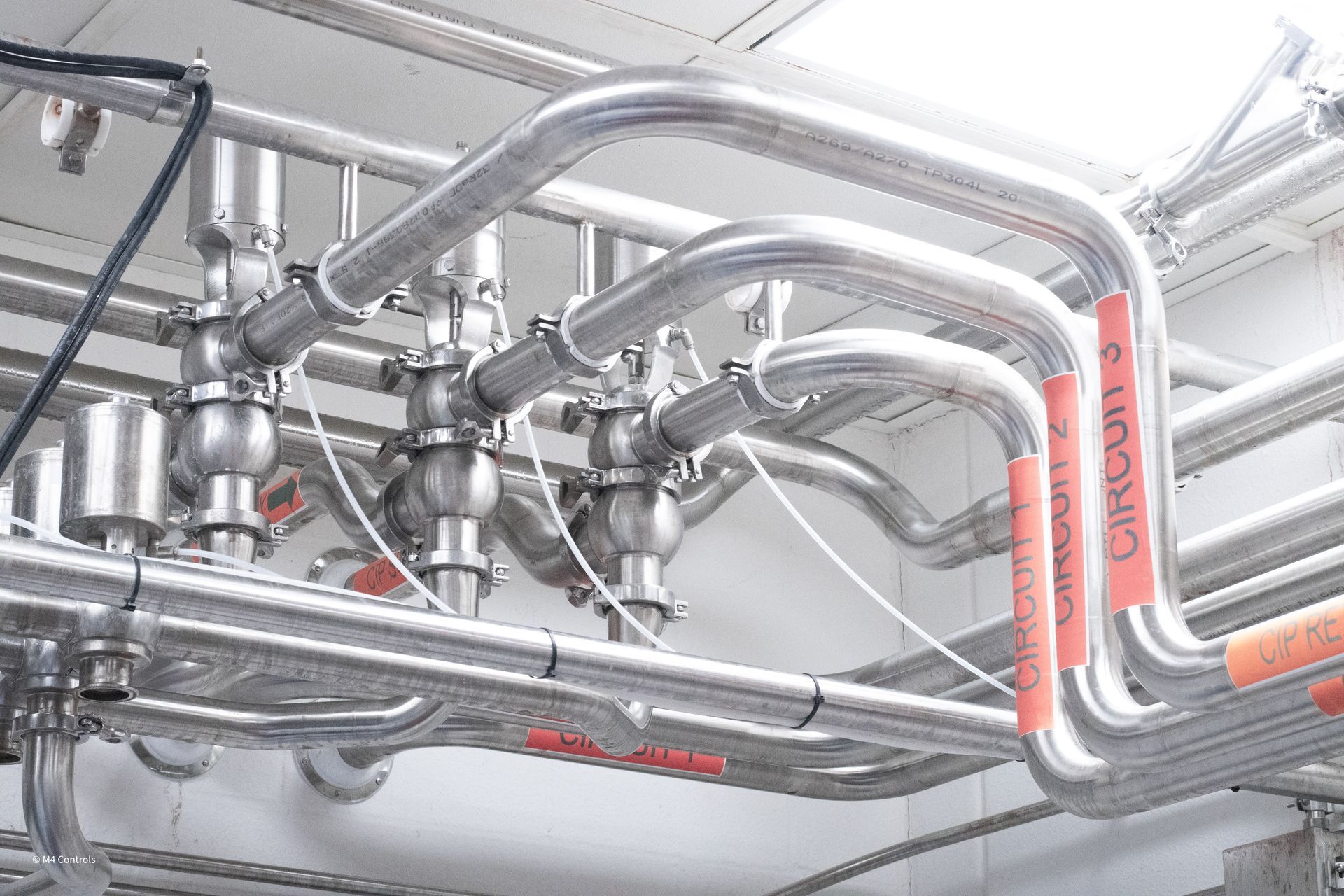

- Sanitation & Maintenance – Ensuring all equipment meets hygiene and upkeep standards.

- Process Line Layouts – Designing efficient production line configurations.

- Lean Manufacturing Principles – Applying methods to reduce waste and improve efficiency.

- Plant Overview & Mass Balancing – Evaluating inputs, outputs, and process flow.

- Factory Expansions – Planning and executing facility growth projects.

- Regulatory Support – Assisting with changing compliance requirements.

- Process Timing Simulation – Testing and optimizing production schedules.

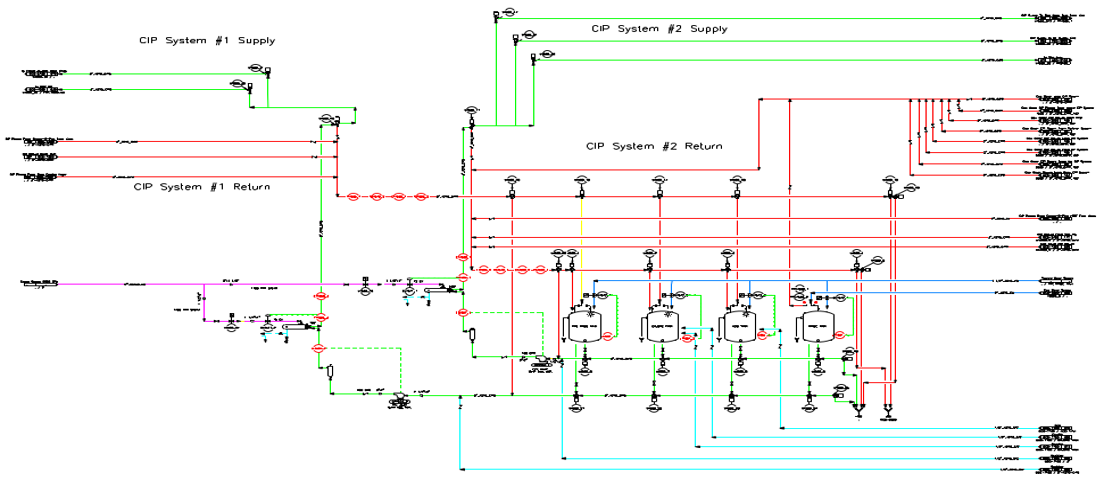

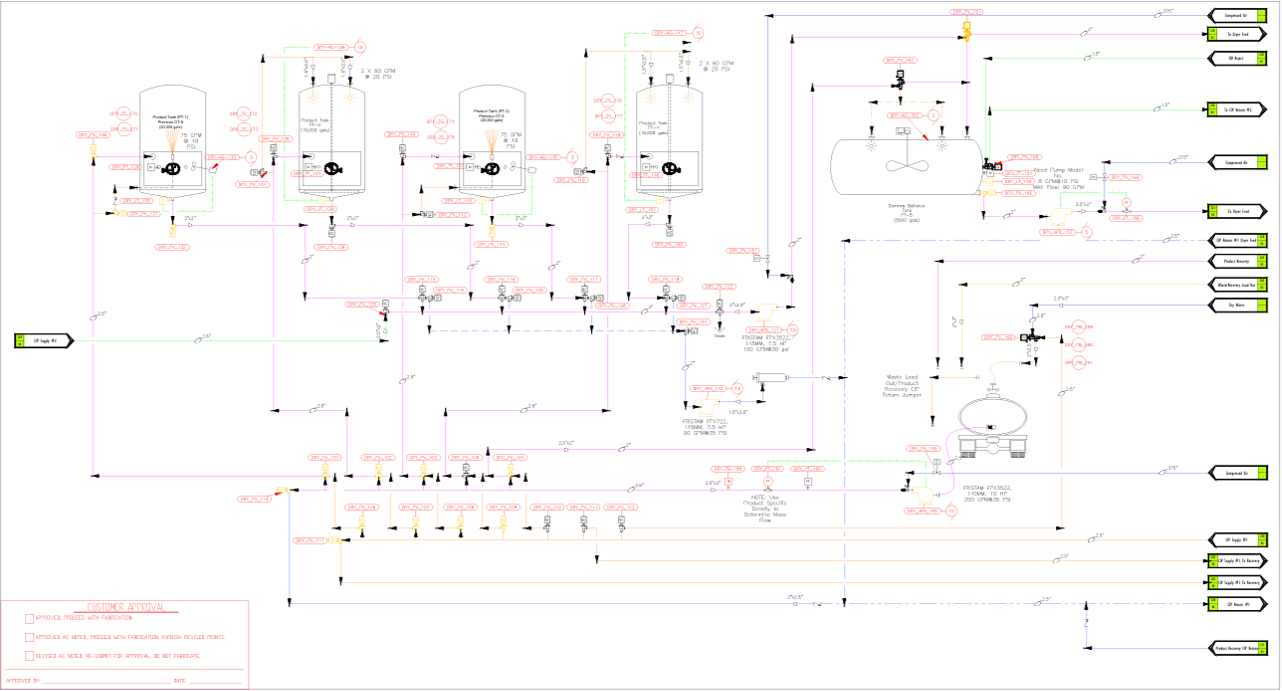

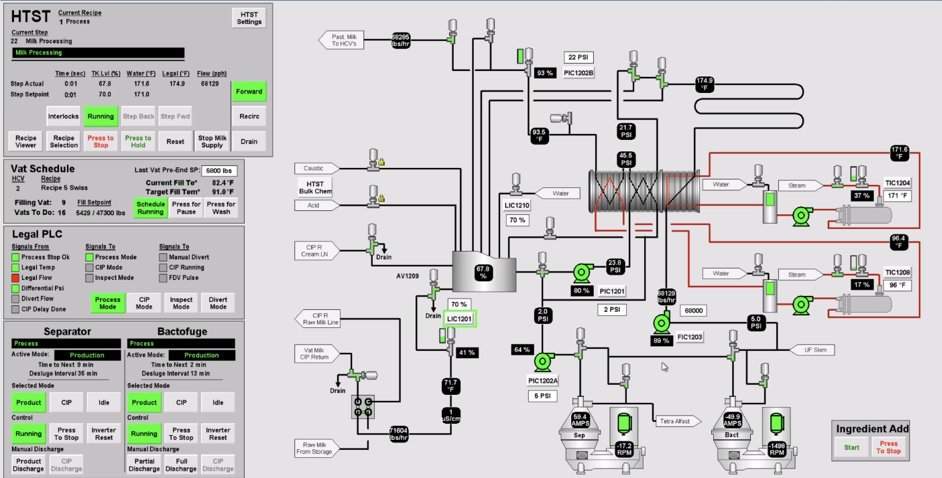

- P&ID’s (Process & Instrumentation Diagrams) – Creating detailed system schematics.

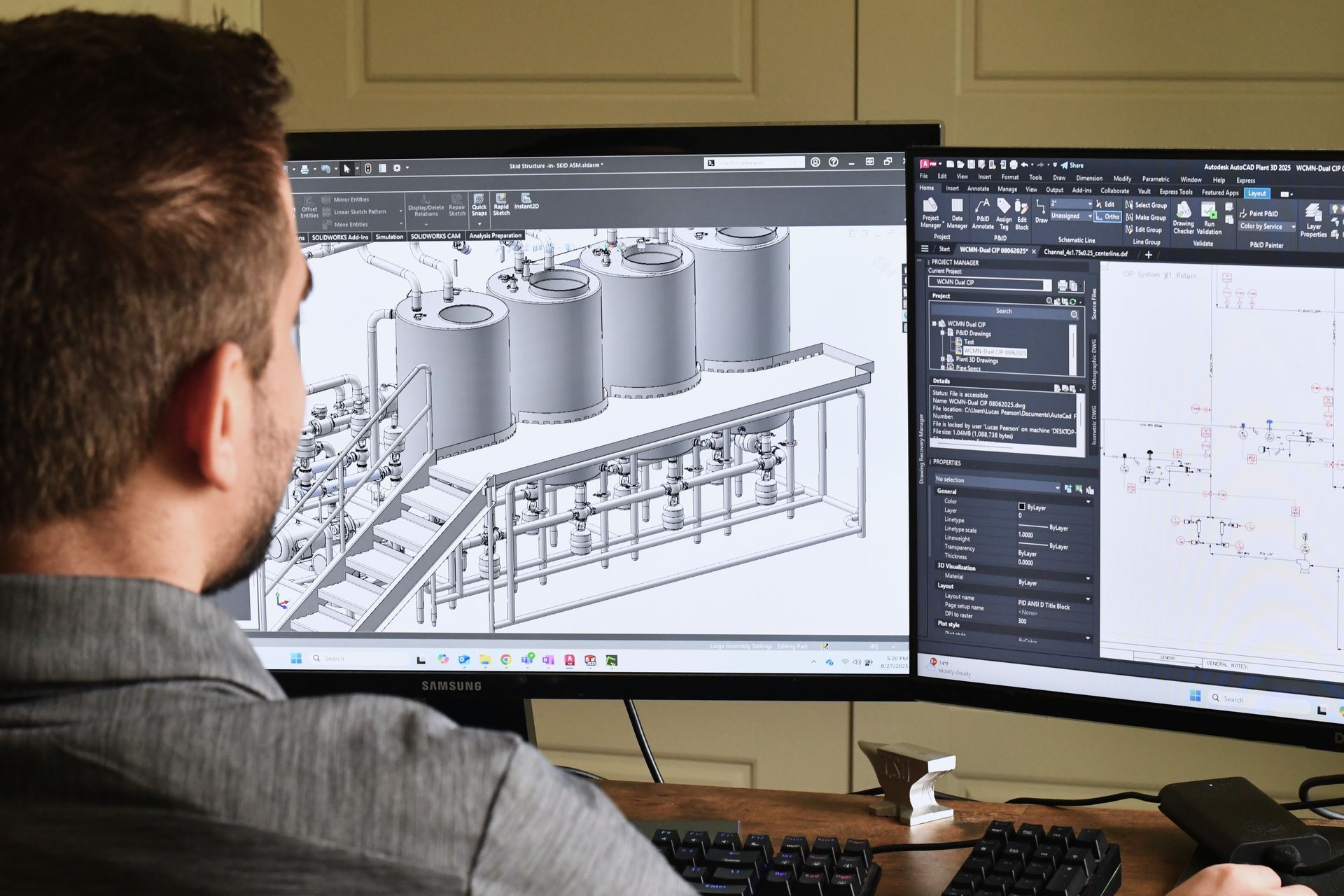

- 3D Models – Developing detailed visual representations of systems.

- Site Support – Providing on-site assistance and expertise.

- Project Management – Overseeing scope, schedules, and resources.

- Commissioning & Start-Up Services – Ensuring systems are installed and operational.

- Process & Implementation Design – Creating structured workflows to ensure smooth, consistent execution.

- Device Ordering & Installation – Coordinating procurement, setup, and functionality testing.

- Customer Support – Providing 24/7 assistance to ensure reliability and satisfaction.

Process and Implementation Design

Process and implementation design focuses on creating efficient, well-structured workflows by carefully mapping out the necessary steps, resources, and responsibilities. This approach ensures that projects move seamlessly from concept to reality, reducing inefficiencies and maintaining consistency throughout execution.

Device Ordering and Installation

Device ordering and installation involves selecting the right equipment, coordinating procurement, and ensuring timely delivery. Once received, devices are installed, configured, and tested to confirm proper functionality, minimizing downtime and supporting seamless operations.

Customer Support

Customer support is a critical part of building trust and loyalty, and offering 24/7 assistance ensures customers always have access to help when they need it. This commitment not only improves customer satisfaction but also demonstrates reliability and dedication to meeting customer needs at any time.

Improved Company Processes Through Automated Systems

Smart Automation for Sanitary Plants

Take control of your operations with reliable, efficient automation solutions designed to simplify your processes and improve productivity. Whether you’re running a food production facility or a dairy plant, our systems are built to deliver convenience, consistency, and cost savings. With our expertise, you can count on solutions that not only meet your requirements but also position your business for long-term success.

Photo & Video Highlights